Wärtsilä will supply its biogas liquefaction technology for an important new project in Mönsterås, Sweden. The system has been ordered by Scandinavian Biogas Mönsterås, a joint venture company between Scandinavian Biogas Fuels (SBF), the majority owner, and local farmers supplying manure and agricultural waste to the project. The plant will produce bio-LNG and will be used as transport fuel for heavy vehicles, thereby contributing to a fossil-free transport system.

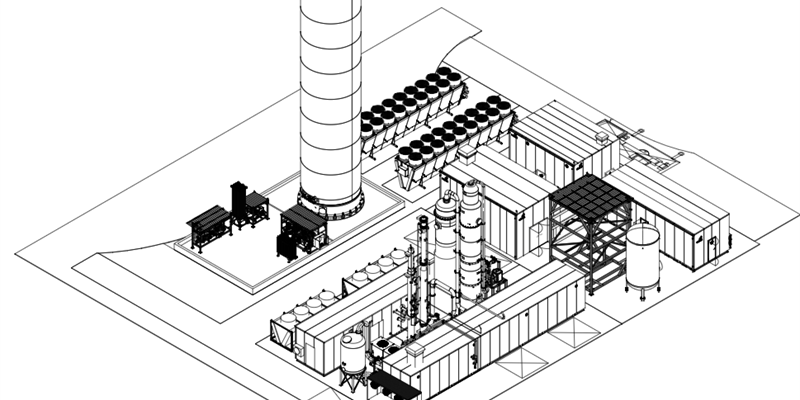

The system will have the capacity to produce 30 tons per day of bio-LNG. It will be the first project of this capacity using Wärtsilä’s amine scrubber type Puregas CA technology to pre-treat the biogas, which is then liquefied using the company’s mixed refrigerant (MR) process. The system will produce biomethane with a negative CO2 footprint, and will thus contribute to a net reduction of greenhouse gases in the atmosphere.

“We are pleased to have once again been selected by Scandinavian Biogas Fuels to supply our biogas liquefaction technology for their latest project. This will be a step-up in capacity from their plant in Norway, and we look forward to strengthening the cooperation between our companies. Decarbonization is central to all Wärtsilä products and solutions, and this project is completely in line with this ambition,” commented Magnus Folkelid, Manager Global Sales, Biogas Solutions.

In addition to the biogas liquefaction system, a bio-LNG storage facility and export station will be supplied. Moreover, a three-year service agreement has been signed. Delivery of the Wärtsilä equipment is scheduled to commence in the first half of 2024, and the plant is expected to be fully operational later that year.

While this 30 tons per day capacity is an advance on earlier systems, Wärtsilä believes that plants with a capacity of as much as 50 tons per day will soon be needed. This is because the biogas industry is being industrialized, and larger plants will be required to capture positive scale effects and synergies. The main challenge to up-sizing will be the availability of substrates (feedstock) from which to produce biogas.

Source: Wärtsilä